Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

| ValueTRUE Micron GearheadsLow cost and ideal for environmentally sensitive applications. Request Quote | View Details |

| UltraTRUE Micron GearheadsFor robotics, aerospace, packaging equipment, and more. Request Quote | View Details |

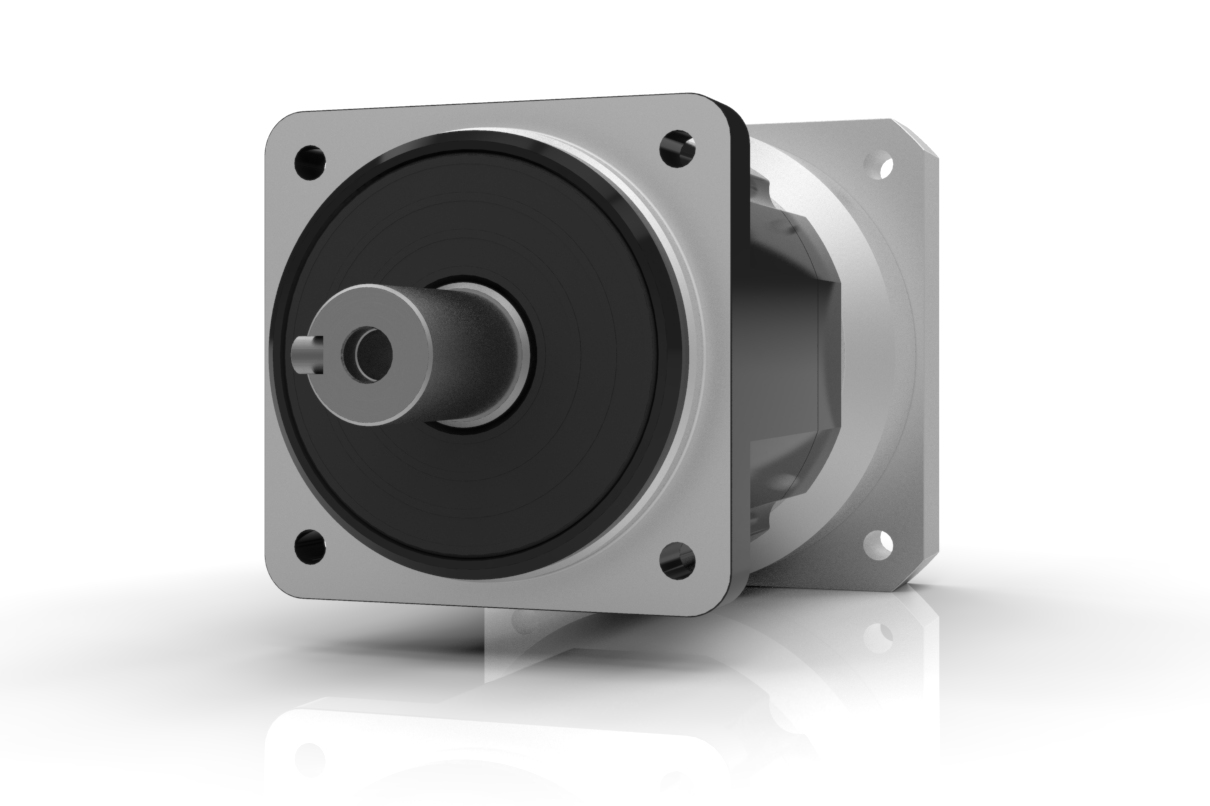

| SPH-W-050-003 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 3:1 Ratio, 20 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-004 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 4:1 Ratio, 20 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-005 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 5:1 Ratio, 20 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-007 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 7:1 Ratio, 18 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-010 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 10:1 Ratio, 15 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-012 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 12:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-015 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 15:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-016 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 16:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-020 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 20:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-025 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 25:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-028 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 28:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-030 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 30:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |

| SPH-W-050-035 A/CSPH-W Series, Parallel In-line, Helical Planetary, Solid Shaft Output, 35:1 Ratio, 13 Nm Max Cont. Torque, Reduced Backlash Request Quote | View Details |