Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

| IMA33 RN10 (1 Stack, 230 VAC)IMA Series, Size 33, 18" (457 mm) Max Stroke, 175 lbf (800 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA33 RN10 (3 Stack, 230 VAC)IMA Series, Size 33, 18" (457 mm) Max Stroke, 425 lbf (1900 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA44 BN10 (230 VAC)IMA Series, Size 44, 18" (457 mm) Max Stroke, 875 lbf (3890 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA44 RN10 (230 VAC)IMA Series, Size 44, 18" (457 mm) Max Stroke, 825 lbf (3700 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA55 BN10 (230 VAC)IMA Series, Size 55, 18" (457 mm) Max Stroke, 1475 lbf (6560 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA55 RN10 (230 VAC)IMA Series, Size 55, 18" (457 mm) Max Stroke, 1375 lbf (6100 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

| IMA33 BN10 (3 Stack, 230 VAC)IMA Series, Size 33, 18" (457 mm) Max Stroke, 450 lbf (2000 N) Max Cont. Thrust, 230 VAC Winding Request Quote | View Details |

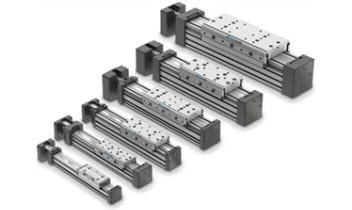

| ERD15 BNM10ERD Series, Size 15, 24" Max Stroke, 200 lbf Peak Thrust, 40.2 in/s Max Speed Request Quote | View Details |

| ERD20 BNM10ERD Series, Size 20, 24" Max Stroke, 500 lbf Peak Thrust, 19.7 in/s Max Speed Request Quote | View Details |

| ERD22 RNM10ERD Series, Size 22, 16" Max Stroke, 850 lbf Peak Thrust, 20 in/s Max Speed Request Quote | View Details |

| ERD22 BNM10ERD Series, Size 22, 39.4" Max Stroke, 900 lbf Peak Thrust, 49 in/s Max Speed Request Quote | View Details |

| ERD25 RNM10ERD Series, Size 25, 16" Max Stroke, 1500 lbf Peak Thrust, 23 in/s Max Speed Request Quote | View Details |

| RSA24 RN10 HTRSA-HT Series, Size 24, 18" Max Stroke, 1556 lbf Peak Thrust Request Quote | View Details |

| ERD25 BNM10ERD Series, Size 25, 39.4" Max Stroke, 1750 lbf Peak Thrust, 24 in/s Max Speed Request Quote | View Details |

| RSA50 BNM10 STRSA-ST Series, Size 50, 48" Max Stroke, 1926 lbf Peak Thrust Request Quote | View Details |