Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

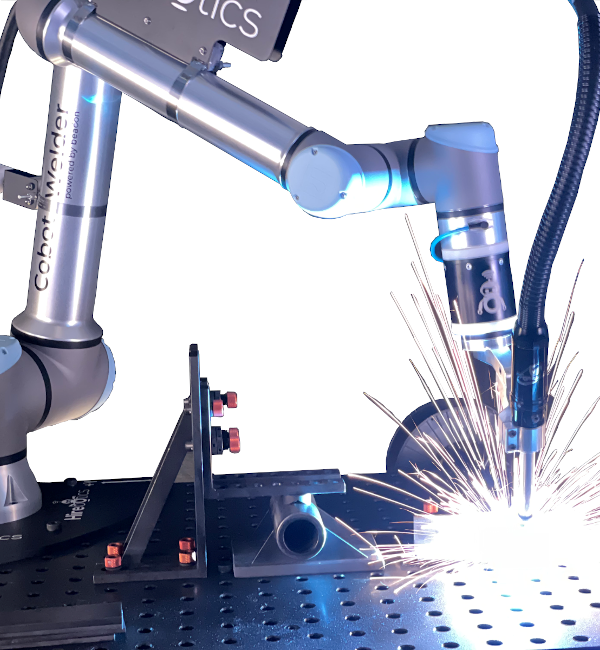

Hirebotics Cobot Welding Solution

The Hirebotics cobot welding robot package is an easy-to-use Collaborative Robot (also known as a cobot) welding system that empowers your company with an inexpensive fast-commissioned automated welding solution. Cobots from Universal Robots are amazing machines that can help your team weld quickly and easily without the added safety concerns of traditional welding systems or welding robots. Electromate’s cobot welding solution offers an affordable cobot welding robot system that’s easy to use and set up.

Easy to Program

If you're looking for a way to speed up your production, a cobot welding robot may be perfect. Thanks to Hirebotics next-generation welding app, you can leverage your current experienced welders to program the cobot welder, allowing you to keep your employees and not hire new software engineers. Who better to program a welding cobot than a veteran welder! Most welders can pick up the software in minutes, allowing less downtime and more time for production .

The Cobot Welding Kit System Includes:

- Universal Robots UR10e Collaborative Robot (51" reach)

- Miller Cobot Welding Package, including an Invision 352 MPa pulsed welder and S74 feeder

- Tregaskiss Tough Gun MIG welding gun

- Hirebotics' Smart Puck for software-free teaching

- Siegmund 48" x 32" welding cart

- Operator panel with emergency stop

Understanding the State of the Welding Industry

Based on recent estimates by the American Welding Society, it is projected that 300,000 welders are needed by 2024 with many experienced welders retiring soon, as the average age of current welders is 55. This factor will leave a big gap of needed experienced welders, and with 20% of welders under the age of 35, the time to upgrade to welding automation is now. Let Electromate help you find the solutions you need to make this transition.

300,000

Number of Welders needed by 2024 to keep up with demand.

55

The average age of the current Welder.

20%

The percentage of Welders that are under the age of 35.

How Hard is it to Make the Switch to a Automated Welding Solution?

US BASED ROBOT INSTALLS

Has slowed down 14% over 2 years compared to South Korea 20% and China 93%

PERCEPTION OF COMPLEXITY

Requires company to hire and train multiple skilled robot programmers and technicians

SKILLED ROBOT TECHNICIANS ARE HARDER TO FIND

SMEs, are concerned with adopting “lights-out” automated operations due to a lack of trained robot technicians

RESISTANCE TO CHANGE

Some welders are resistant to the shift to new technologies

LOWER ROBOTICS ADOPTION

Less than 25% of Automation companies surveyed are planning to add robots in the next year

How Can the Welding Cobot Improve Operatiions and Business?

Safer work conditions for Employees

Better overall product quality and adherence to standards

Reduce human error and operational costs

The ability to weld with new materials

Increased production capacity and flexibility

Improved weld integrity and repeatability

How Can the Welding Cobot Solution Solve Your Labor Shortage?

It's very easy to program.

There's no need to hire robot programmers.

Takes less than a day to setup & start production.

Increases the productivity of your existing welders.

Sample image only. Product may differ