Reprint of blog p Ryan Klemetson of Tolomatic on Tue, Mar 24, 2015 @ 08:03 AM

Many process industry control engineers are looking to more sophisticated motion control solutions for valve automation. That’s because there’s an ever-growing need to improve productivity, increase efficiency and minimize downtime. It’s essential that engineers be able to control the valves that regulate the flow of materials throughout a facility.

There are two basic ways to operate control valves: linear motion (rising stem) and rotary motion (half turn or quarter turn). Powered rising stem valves are often used in mission critical areas of a process. In these applications reliability, repeatability, accuracy, and responsiveness are crucially important. These factors impact the type of valve actuation specified.

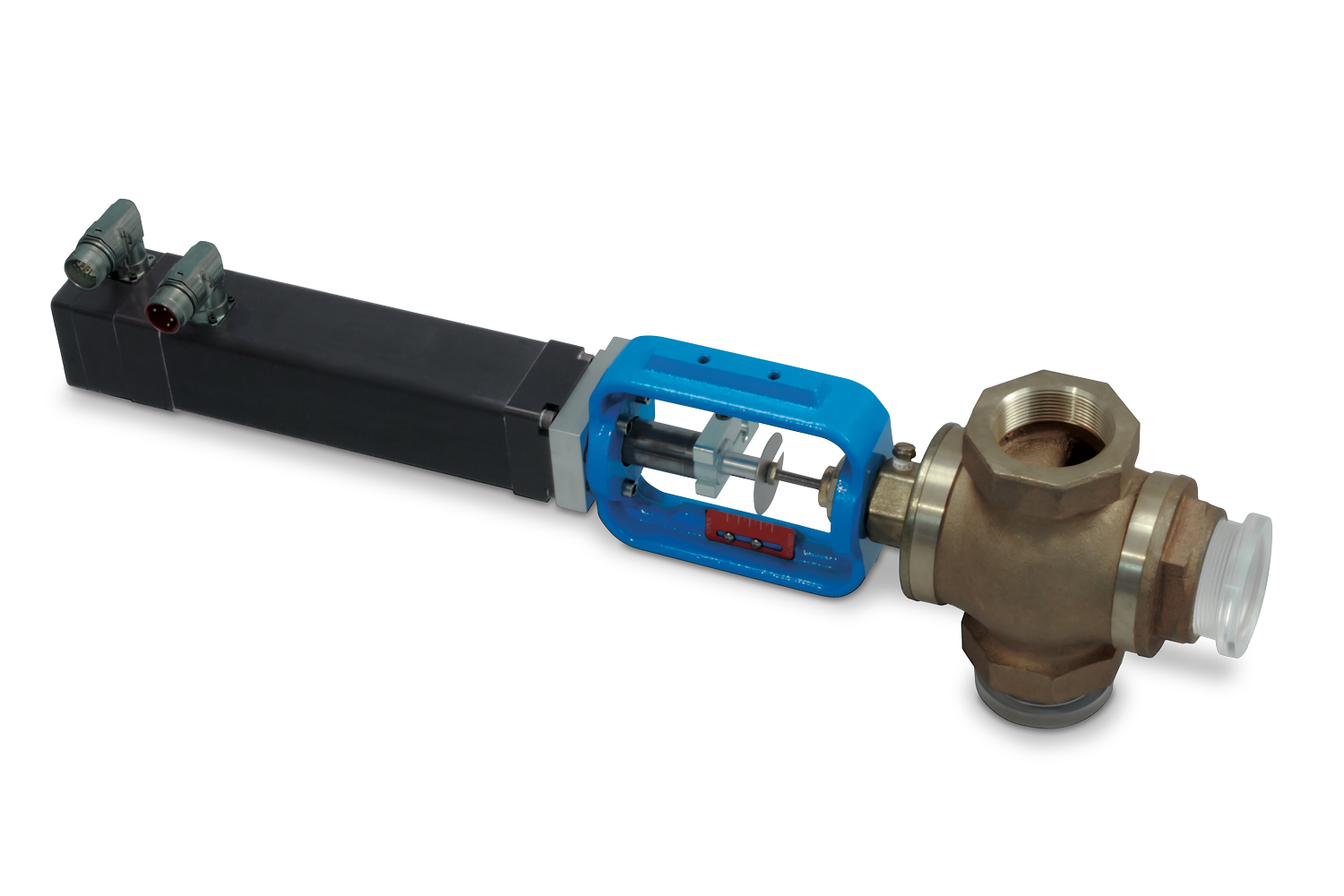

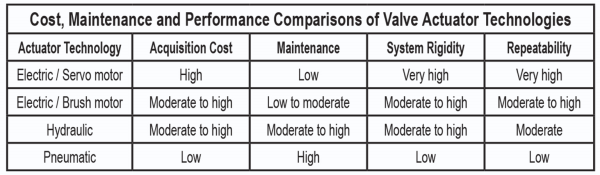

Rising stem valves require linear actuation, and control engineers have a choice in actuation technologies. There are traditional methods: pneumatic or hydraulic actuated systems and electric valve actuators driven by brush servo motors. Then there’s an emerging technology: brushless servo motor driven electric valve actuators.

Here’s an explanation from Tolomatic of what these technologies can do.

Fluid power versus electric

Fluid powered valve actuators, whether pneumatic or hydraulic, are common throughout the process industries. They can handle open/close applications well, are inexpensive to buy and are straightforward to install and operate. However, they can have major drawbacks:

- Pneumatic actuators perform poorly in applications that require incremental movement of the valve stem.

- Ambient temperatures affect fluid viscosity and actuator performance.

- Leaks and potential fluid contamination can result in low operating efficiency.

- Maintenance requirements can be expensive

Due to these drawbacks, electric actuator systems are used in many control valve applications. They offer a cost effective alternative to pneumatic or hydraulic valve actuation.

An all-electric system may have a higher purchase price than its pneumatic or hydraulic counterpart, but has fewer components and needs minimal maintenance. Electric systems are simple to integrate into most control schemes and have field bus communication protocols available as a standard feature or option. Diagnostics, programmability, safety limits, and data logging capabilities are also available.

Brushless versus brush servo motors

Many electric valve actuators use a brush servo motor to power the actuator because these motors are an inexpensive way to get the increased performance, reliability and safety required in many process environments. This technology has been time tested in the field. However, what makes the brush servo motor a cost effective solution is also the source of its limitations.

These motors have physical brushes which contact the rotor. Frequent cycling of power to start and stop motion causes the motor to wear out quickly. It is not uncommon to see these actuator systems with a duty cycle limited to no more than 3600 starts/stops per hour.

This limited duty cycle is not an issue when brushless servo technology is used. Brushless servo motors are a very reliable, robust way to control linear actuators and are 100% duty cycle rated. Brushless servo motors are higher in cost than brush motors, but they are becoming more widely used in process industries because of this higher duty cycle rating and the greater degree of control they allow.

duty cycle rated. Brushless servo motors are higher in cost than brush motors, but they are becoming more widely used in process industries because of this higher duty cycle rating and the greater degree of control they allow.

As the name implies, brushless servo motors do not operate like brush motors. Rather than passing current through an armature (which is where the brushes come in), brushless servo motors use a permanent magnetic rotor and a wound stator. Power is passed through the stator, and alternating polarities though the different phases of the motor stator cause motion. Brushless servo motors are able to operate more smoothly and at greater speeds (10,000+ RPM) than brush servo motors.

Brushless servo motors must have continuous position feedback of the rotor to maintain proper phasing and function. The feedback device is also the component that communicates position to the controller to enable very high resolution, accuracy, and repeatability. Position, speed and torque can be precisely controlled and continuously monitored with a brushless servo motor. These motors can automatically compensate for varying conditions exerted upon the mechanical end effector attached to the stem.

Tags: Linear Actuation, Servo Motor, Fluid Power vs. Electric