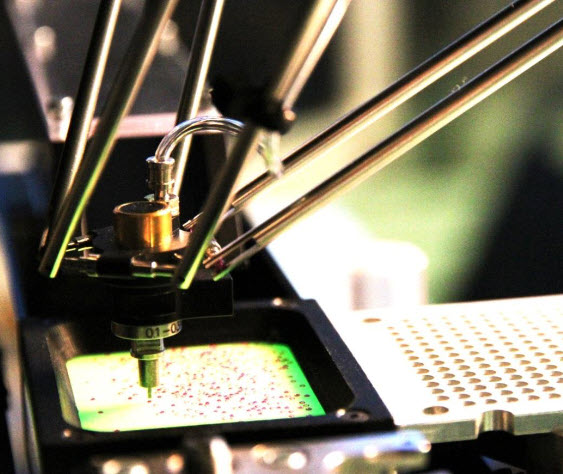

Delta Robots for Microassembly Tasks

Asyril develops and integrates mechatronic systems for fast, flexible, and automatic handling of small components. They recently revolutionized the market using Delta robots with Maxon motors to ensure highly precise and dynamic movements. In their quest to find the most promising solution for systems that are capable of handling microtechnical components, they concluded that it was parallel kinematic structures. From here, they developed the Delta configuration. In this configuration, Maxon motors provide the movement of the kinematic elements, but are not themselves moved. This is because the motors are attached directly to a support frame and then send movement straight to the structure.

Drive Technology for Microassembly

Not only did the mechanical components need to be miniaturized, but the drives as well. In the Pocket Delta, Aysil used micromotors from Maxon motor. Its parallel mechanism is driven by three EC-i 40 motors mounted to a plate above the robot. Due to this, the mass to be moved is low and the robot is highly dynamic with a repeat accuracy of less than 3 micrometers. The Maxon brushless DC motors have a small diameter of 40 mm with a power of 40 Watts. These micromotors are connected directly to high-resolution rotary encoders in order to detect position.

The Pocket Delta is one of the fastest and most precise robots in its sector, with no gearhead required. It is particularly well suited for sorting, selecting, and machining micro-components in the watch industry. However, it is also used in medical technology and the electronics/semiconductor industries.

For more information regarding the Maxon motors used in the Delta robots, view the full article here or contact Electromate now!