The HETDEX project (Hobby-Eberly Telescope Dark Energy Experiment) is the first major attempt to find and examine “dark energy” in the universe. Through this project, we are able to record three-dimensional positions of one million galaxies using special spectrographs. In the summer of 2012, the Hobby-Eberly Telescope began scanning the universe with the help of maxon motors for telescopes.

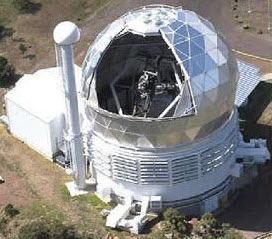

Hobby-Eberly Telescope (HET)

The Hoby-Eberly Telescope is located at the McDonald Observatory in West Texas and contains a spherical mirror with 91 identical hexagonal segments, each one meter in size. These mirror segments for a mirror with a diameter of 11 meters, making it the largest in the world. The HET in and of itself is the fourth largest optical telescope in the world, but due to its innovative design, it was cost-effective to make. Costing around $13.5 million, the HET cost about ¼ the cost of a comparably large telescope.

This spectroscopic telescope is mounted on a Prime Focus Instrument Package (PFIP) equipped with two spectrographs. The mirror always points at a position 55 degrees above the horizon, but it can be swiveled horizontally full circle, allowing it to observe 70% of the skies.

In future projects, upgrades to the wide field components will increase the angle of view to 22 arc minutes and usable aperture to 10 meters, making it possible to gather the highest possible light quantity via glass fiber coupling. These upgrades will revolutionize spectroscopic observation.

Scientists want to use this upgraded version of the HET to obtain a better understanding of “dark energy.” Current hypotheses stipulate that almost ¾ of all matter and energy in the universe consists of “dark energy.” Dark energy is considered to be a mysterious force that causes the universe to drift apart at increasing speeds at it ages.

HETDEX Looks to the Universe

The goal of the Hobby-Eberly Telescope Dark Energy Experiment (HETDEX) is to examine dark energy and determine whether the current laws of gravity are correct. Scientists also hope to gather new astronomic details surrounding the Big Bang. From 2012 to 2015, the portion of the sky that includes the Big Dipper will be scanned by the HET. This project hopes to map 1 million galaxies that are up to 10 to 11 billion light years away from earth.

PFIP Design

The PFIP is positioned on a tracking device at the top of the telescope. It is equipped with a wide field correct, capturing camera, measuring devices, and a focal plane system. This standalone automation unit consists of 12 subsystems and 24 movement axes. Of the movement axes, 15 of these are motorized. The movements need to be smoothly and precisely executed at various speeds – in particular, extremely slow speeds. Additionally, the motion controller must be able to perform multiple operations in different situations such as following a velocity curve, moving to and holding an absolute position, and more.

maxon Brushless EC Motors

The PFIP subsystems utilize brushless EC motors from maxon motor. These telescope brushless motors are equipped with gearheads, magnetic incremental encoders, and electrically operated brakes as needed. Smooth motion at low speeds is achieved using sinusoidal commutation. As such, an optional incremental encoder is used in addition to the standard Hall sensors, providing additional position data to the motion controller.

Accurate maxon Positioning Control Units

All controllers used are maxon type EPOS2 50/5 featuring:

- Close-loop control circuits for current, velocity, and position

- Interpolated motion mode allowing them to follow a programmed multi-axis trajectory

- Digital and analog input/output devices

With these controllers, it’s also possible to program reactions to digital input signals such as home position, quick stop, and drive activation/deactivation. In order to be compliant with the specs for the PFIP and HET, all components had to be able to function at temperatures of -10˚C or below. Maxon motor offers a range of products that can meet not only the temperature requirement, but also provide the quality, reliability, and ruggedness required for industrial automation systems.

For more information regarding telescope brushless motors & motion controllers, contact Electromate today.