While it may seem counter-intuitive, there are instances where it makes sense to use an off-the-shelf 6-axis robot arm instead of having a system designed because you only require three or four degrees of freedom. Using an off-the-shelf 6-axis robot arm can save money, time, space, and energy compared to a custom system.

Lower capital investment with a 6-axis robot arm

Designing a multi-axis system takes time, which adds to engineering expenses. A multi-axis system can be as simple as a couple of linear guides stacked on top of each other (a so-called gantry robot) or as complex as a six-axis parallel robot with dozens of linkages, and universal and ball joints. But even the simplest gantry system requires you to choose the right linear guides, design and machine adapter plates, and implement a motion controller. If you will be using hundreds of the systems being designed, then the design cost will be spread out, but for a few systems, it can often make more sense financially to simply use an existing 6-axis robot, even if it seems over-engineered for the purpose. With an already designed system, you share the design cost with everyone else using the same 6-axis motion component.

Faster availability and implementation using the Meca500

In addition to the time it takes to design a custom multi-axis system, the project plan needs to include the time it takes for each component to be received. With supply chain issues, you might end up waiting for months for a motor to be delivered. Anything unexpected can further delay the delivery of the final product. With a standard 6-axis robot, like our Meca500, the robotic component is often in stock, ready to use.

Additional time is saved during implementation. Since the Meca500 can interface with any computer or PLC, you can easily operate the robot using your preferred programming language. Many custom-designed systems will require you to use proprietary programming, which takes time to learn.

Smaller footprint and lower energy consumption with a compact 6-axis robot

A custom-designed robot is likely to be big and bulky without spending extra time to refine and revise the design to minimize the footprint. A custom-built system will also likely have a big controller and long, thick cables, though this is the case with most six-axis robots as well. With an off-the-shelf compact component like the Meca500, the unit has already been designed to have a minimal footprint. The Meca500 controller is embedded, so the complete system is extremely compact and saves space. You benefit from all the development that’s already gone into this product.

In addition to taking up less space, a smaller component is easier to anchor and will require less bracketing than a larger system. A small unit like the Meca500 is extremely energy efficient too, consuming less electricity than a larger robot.

What can a six-axis robot arm do?

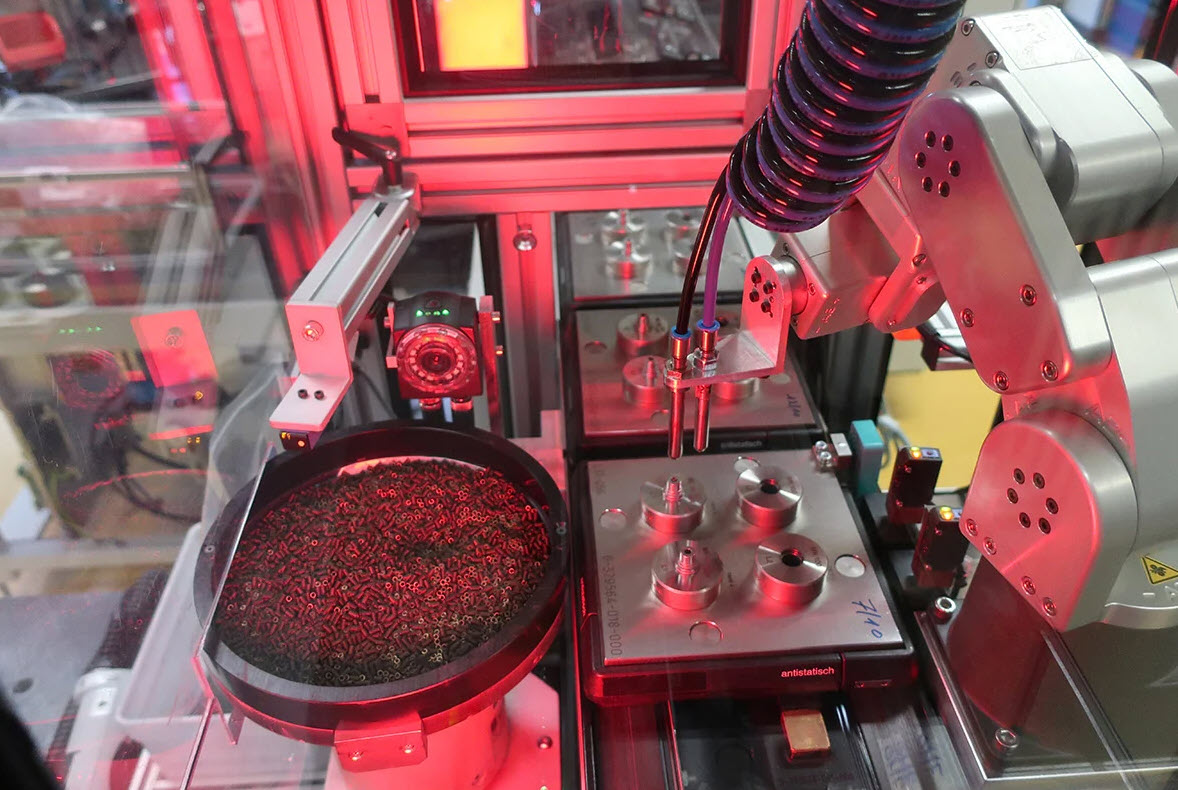

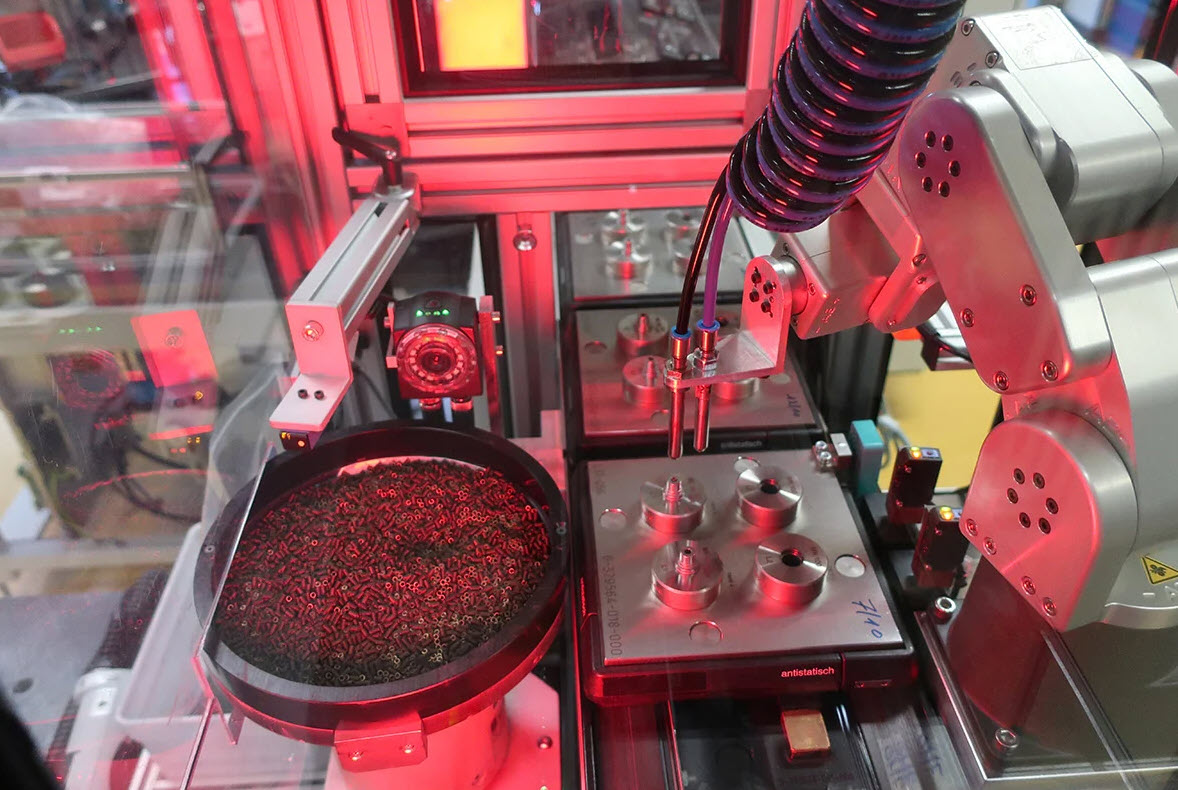

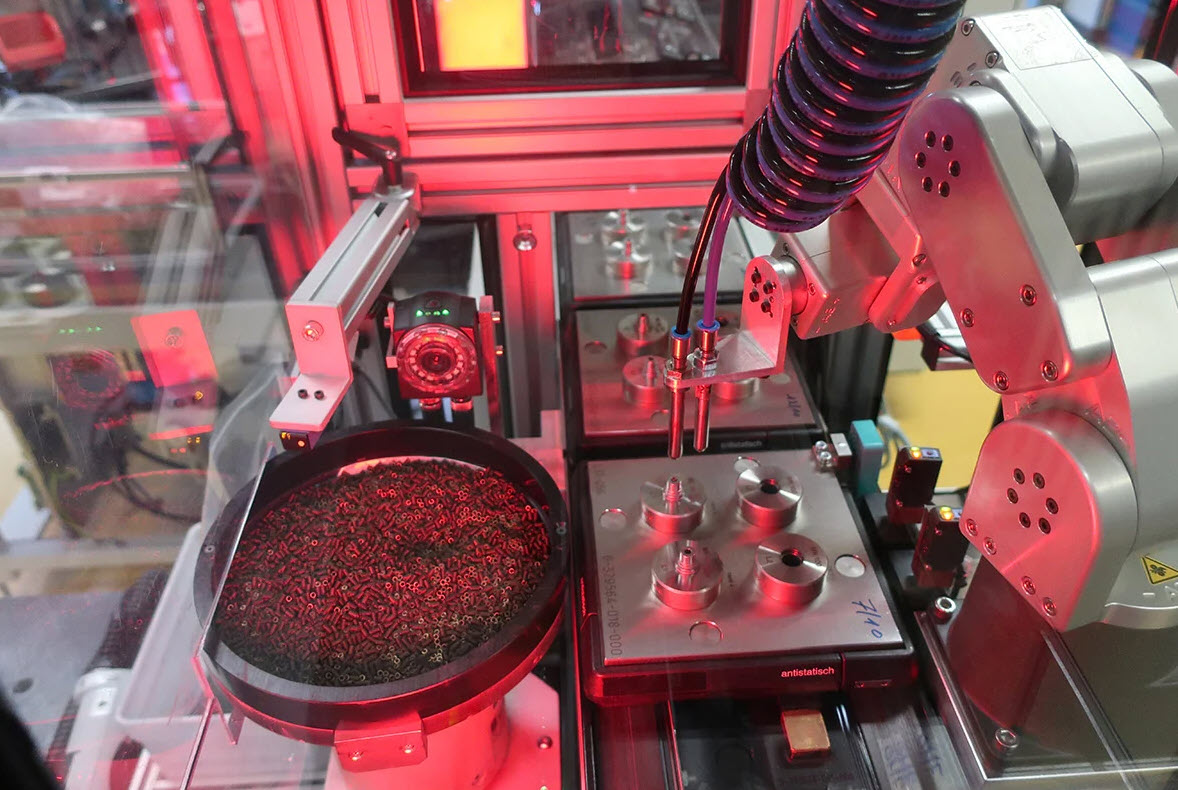

The Meca500 is ideally suited for precision tasks, and can also be used for a wide range of applications, including testing and kitting. For example, in the photo at the beginning of this article, the Meca500 is used to pick and place parts with only three degrees of freedom.

Article Originally published on Feb. 21, 2022 at https://blogs.mecademic.com/why-choose-a-six-axis-robot-arm-over-a-custom-multi-axis-system