Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

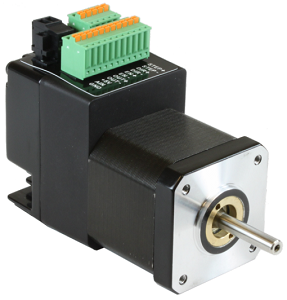

STM17C-3CE

- Buy 10 for $659.00 each and save 3%

The STM17C-3CE integrated stepper is a drive+motor unit, fusing a NEMA 17 step motor and a sophisticated 2.0 A/phase (peak-of-sine) stepper drive into a single device. Power to the drive, located at the rear of the motor, must be supplied by an external DC supply. The STM17C-3CE integrated stepper is designed to operate on a CANopen communication network and conforms to Can in Automation (CiA) DS301 and DSP402 specifications. It supports Profile Position, Profile Velocity, and Homing modes, as well as the ability to run stored Q programs via Applied Motion-specific CANopen objects.

All STM17 units are setup and configured using Applied Motion’s ST Configurator™ software.

An integral 1000-line (4000 count/rev) incremental encoder is housed inside the same enclosure as the drive electronics, providing protection from dust and debris. The integration of the encoder means the STM17C-3CE can perform special functions not available otherwise. Stall Detection notifies the system as soon as the required torque is too great for the motor, which results in a loss of synchronization between the rotor and stator, also known as stalling. Stall Prevention actually prevents stalling of the step motor by dynamically adjusting motor speed to maintain synchronization of the rotor to the stator under all conditions. This unique feature allows step motors to operate in a much broader range of applications than previously available to step motors, such as torque-control applications. The Stall Prevention feature also performs static position maintenance, which maintains the position of the motor shaft when at rest.

Each STM17 integrated stepper comes with 3 digital inputs, 1 digital output, and 1 analog input. The digital inputs accept signals of 5-24 VDC and can be used for connecting pulse & direction signals, end-of-travel limit switches, jog switches, quadrature encoder signals, PLC outputs, sensors, or many other signal types. The digital output can be connected to PLC inputs, counters, lights, relays, or other devices. The analog input accepts 0-5 VDC signals and can be used for velocity and position control.

The STM17C-3CE comes with an RS-232 port for programming and a CANopen port for network communications.

Features

| Manufacturer | Applied Motion Products |

|---|---|

| Communication/Interface | CANopen, RS-232 |

| Feedback | Incremental Encoder |

| Max Holding Torque (mNm) | 480.00 |

| Max Holding Torque oz (in) | 68.00 |

| Max Length (mm) | 107.50 |

| Min Operating Temperature (°C) | 0.00 |

| Min Operating Temperature (°F) | 32.00 |

| Max Operating Temperature (°C) | 85.00 |

| Max Operating Temperature (°F) | 185.00 |

| Shaft Diameter (mm) | 5.00 |

| Shaft Diameter (in) | 0.20 |

| Max Input Supply Voltage (VDC) | 48.00 |

| Motor Construction | Hybrid Stepper |

| NEMA Frame Size | 17 |

| Number of Axes | 1 |

| Operating Mode | CANopen |

| Rotor Inertia (kg-m-s²) | 8.19E-06 |

| Rotor Inertia (oz-in-s²) | 1.16E-03 |

| Setup | Software Setup |

| Shaft Orientation | In-line,Double-ended (Encoder mounted) |

| Step Angle (°) | 1.8 |

| Product Category | Integrated Motors |

Sample image only. Product may differ