Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

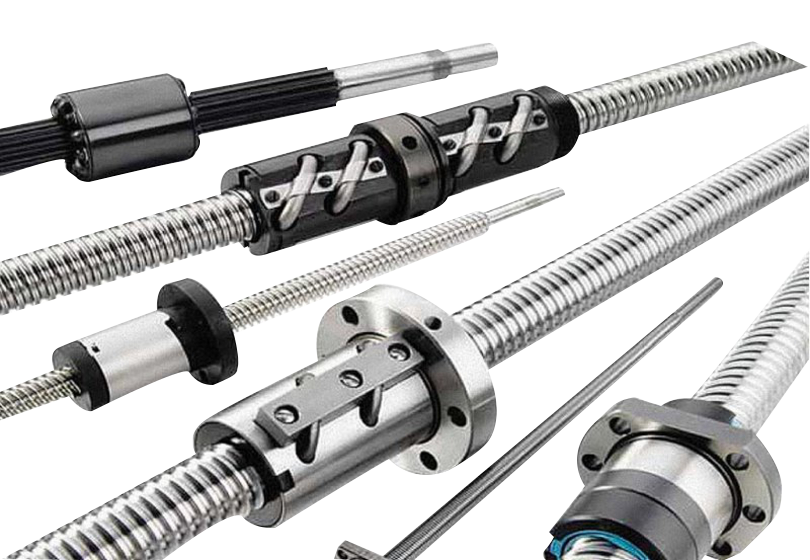

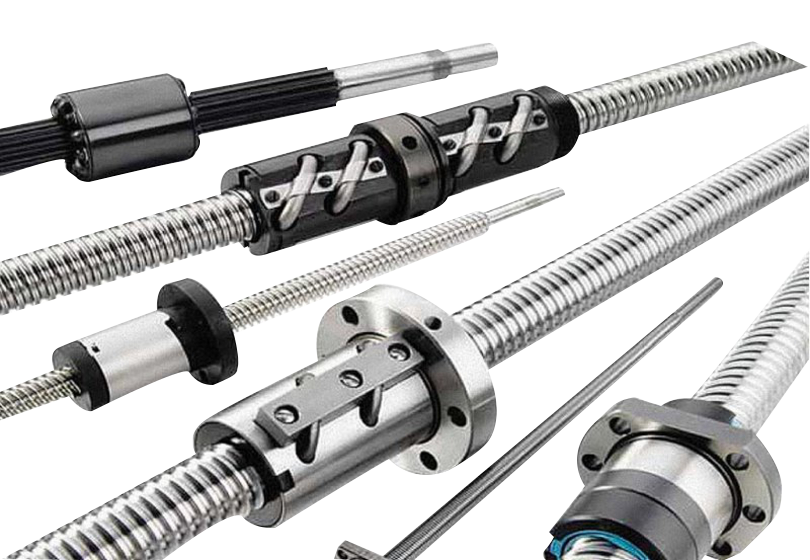

Ball & Acme Screw Products

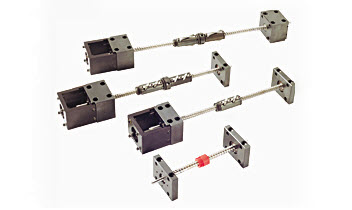

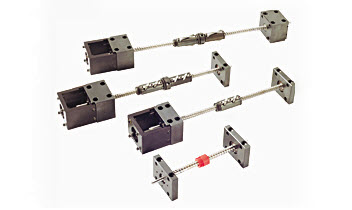

The main function of ball & acme screw assemblies is to provide a drive mechanism, usually within a positioning table, to move a load. The drive mechanism is an element that contributes to position accuracy, repeatability, speed, and mechanical system resolution. This results in low wear and long life. Key Features of a Ball Screw System are:

- Rolled Ball Screw system utilizes a tapped nut with a standard accuracy grade rolled screw.

- Precision Rolled Ball Screw system utilizes a ground nut with a higher accuracy grade rolled screw.

- Ground Ball Screw system utilizes a ground nut with a high accuracy precision ground screw, and provides the highest performance and accuracy.

What are Ball Screws?

Ball Screws are the screw of choice for high duty cycle, high speed, and long life applications. The ball screw nut uses one or more circuits of recirculating steel balls which roll between the nut and ball screw grooves, providing an efficient low friction mechanical drive system.

The nut, which is attached to the table carriage, moves back and forth in parallel with the linear bearing system as the ball screw rotates. Using a higher lead ball screw (for example a 0.500 inch lead instead of a 0.200 inch lead) will offer greater carriage speed for applications requiring rapid traverse, or fast, short incremental moves.

What are Acme Screws?

Accuracy grades of acme screws and ball screws are typically reflected by their "lead error" specification, which is generally given in a "in/ft" (microns/300 mm) rating. This "lead error" is the primary element in determining the position accuracy of a positioning table. The lower the "lead error" (better position accuracy), the more costly the drive screw assembly.

Acme Screws typically use a turcite (polymer) or bronze nut. The nut, which is attached to the table carriage, moves back and forth in parallel with the linear bearing system as the acme screw rotates. The threads of the plastic or bronze nut ride in the matching acme screw threads, much like an ordinary nut and bolt system. This produces a higher friction (thus lower efficiency) system than a ball screw assembly, since there are no rolling elements between the nut and the acme screw threads. Acme screws work fine for applications requiring low speeds, low noise and low duty cycles. Acme screws are also a good choice for most vertical applications as they typically prevent back-driving of the attached load. However, in some applications the friction of the acme screw can affect low speed smoothness and its long term life is significantly lower than a ball screw.

A turcite nut option is available with rolled ball screws and operates very similar to an acme screw. However, the polymer nut contacts the ball screw grooves differently than an acme screw assembly producing a drive mechanism that has less friction than an acme screw thereby allowing for potential higher speeds and less input torque required from a coupled motor. This option provides smooth motion, low audible noise, and is ideal for vertical applications. Also, using the turcite nut with high lead ball screws provides for faster linear speeds.

Ball & Acme Product Lines we Carry:

Lead Screw Assemblies

Available in standard diameters from 1/8" (3.2mm) to 15/16" (23mm), with standard leads from .012" to almost 4" (0.30mm to 92mm) including metric and left hand threads. Custom sizes and leads can be special ordered.

Precision Ground Ball Screws

Precision ground ball screws offer high efficiencies and long life. They will produce a lower audible noise and the highest motion smoothness as compared with lower grade screw and nut assemblies. These assemblies are 100 percent duty cycle products. The GS series have dynamic loads to almost 1000 lbf and static loads to just over 3000 lbf. Service life with the above values is 1 million inches of travel but can be calculated to 100 million inches of travel with reduced loads.

Precision Roll Thread Ball Screws

Designed to maximize performance while providing design flexibility. These assemblies utilize a precision ground ball screw with precision ground preloaded nuts. A ground ball screw will offer better open loop (no encoder feedback) position accuracy versus a rolled or precision rolled ball screw. This grade of screw assembly is used for very precise motion requirements, low lead error, low velocity and torque ripple due to mechanics.

Rolled Thread Ball Screws

Rolled screws using ball nuts offer high efficiencies and long life but have audible noise and are the least smooth option. The solid nut will give the least audible noise and the smoothest motion but have the shortest life span and lowest efficiency. The ball nut assemblies are 100 percent duty cycle, while the solid nut versions are only up to 50 percent duty cycle.

Ball Screw Lubricant

We offer a full complement of lubricants including our low vapor pressure greases for clean room and vacuum applications. The TriGel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Choose the appropriate gel for your requirements and get the utmost performance out of your ball and lead screw products.