Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

Hybrid Stepper Motor Linear Actuators

Haydon Kerk Motion Solutions offers a unique line of Hybrid Stepper Motor Linear Actuators that open new avenues for equipment designers who require high performance and exceptional endurance in a very small package. The various patent pending designs of Haydon Kerk stepper linear actuators use a proprietary manufacturing process, which incorporates engineering thermoplastics in the rotor drive nut and a stainless steel acme lead screw. This allows the linear actuator to be much quieter, more efficient and more durable than the v-thread and bronze nut configuration commonly used in other linear actuators. Motor life is improved more than 10 times over the traditional bronze nut style – and it requires no maintenance and does not affect the cost. An additional feature is the bearing pre-load adjustment which, unlike other designs, does not protrude from the motor configuration commonly used in other actuators. Electromate supplies NEMA stepper motor linear actuators throughout Canada.

View a 1minute YouTube video on Haydon Kerk's Size 17 Stepper Motor Linear Actuator: Haydon Kerk Size 17 Stepper Motor Linear Actuator YouTube Video .

Corresponding NEMA Sizes

The Haydon™ brand of hybrid linear actuators come in six sizes, from 21 mm square to 87 mm square corresponding to NEMA size 8, size 11, size 14, size 17, size 23, and size 34. Each size has three designs available – captive, non-captive and an external linear version. There are over twenty different travels per step available, from .00006 inch (.001524 mm) to .005 inch (.127 mm). Micro stepping can be used for even finer resolution.

These linear actuators are ideal for applications requiring a combination of precise positioning, rapid motion and long life. Typical applications include X-Y tables, medical equipment, semiconductor handling, telecommunications equipment, valve control, and numerous other uses.

Haydon Kerk's family of Hybrid Series Stepper Motor Linear Actuators includes:

- Size 8 Linear Actuator

- Size 11 Linear Actuator

- Size 11 DS Linear Actuator

- Size 14 Linear Actuator

- Size 14 DS Linear Actuator

- Size 17 Linear Actuator

- Size 17 DS Linear Actuator

- Size 23 Linear Actuator

- Size 23 DS Linear Actuator

- Size 34 Linear Actuator

- AC Synchronous Linear Actuators

Can-Stack Stepper Motor Linear Actuators

The Haydon™ brand of can-stack stepper motor linear actuators provides both a broader range and, for a given size, significantly higher thrust than previously available from mini-steppers. Five basic frame sizes are available, Ø 15 mm (.59"), Ø 20 mm (.79"), Ø 26 mm (1"), Ø 36 mm (1.4") and Ø 46 mm (1.8"). Available step increments vary with the motor frame sizes and are dependent on the basic step angle of the motor and the lead screw pitch. A captive, external or non-captive shaft (lead screw) option can be supplied for almost every size. The captive shaft configuration features a built-in "anti-rotation" design. The non-captive shaft option requires the customer to provide external anti-rotation. The external linear actuators incorporate a rotary lead screw and an external translating nut. These motors are ideal for applications where there is no space behind the motor for a through-screw design. Both unipolar and bipolar coil configurations are available.

Haydon Kerk Motion Solutions patented design accepts a larger rotor than conventional units, improving efficiency and eliminating the need for massive heat sinks. Unique features impart ruggedness and reliability that assure long life and consistent performance. Rare earth magnets are available for even higher thrust. All units are built with dual ball bearings for greater motion control, precise step accuracy and long life.

Applications include medical instrumentation, machinery automation, entertainment, semiconductor, robotics, sophisticated pumping systems and other automated devices which require precise remote controlled linear movement in a broad range of temperature environments.

Haydon Kerk's family of Can-Stack Stepper Motor Linear Actuators includes:

- 15000 (15mm) Linear Actuator

- 19000 (20mm high output) Linear Actuator

- 20000 (20mm) Linear Actuator

- Z20000 (20mm Z) Linear Actuator

- 25000 (25mm high output) Linear Actuator

- 26000 (26mm) Linear Actuator

- Z26000 (26mm Z) Linear Actuator

- 36000 (36mm) Linear Actuator

- 37000 (36mm high output) Linear Actuator

- 46000 (46mm) Linear Actuator

- AC Synchronous Linear Actuators

IDEA Programmable Linear Actuators

Haydon Kerk Motion Solutions offers the IDEA Programmable Linear Actuator which is an integrated stepper motor based linear actuator, electronic drive and fully programmable control unit. Programming the actuator is through a simple-to-use patent-pending Graphic User Interface (GUI). Programming the actuator is through the use of on-screen buttons instead of complicated proprietary programming languages.

A unique benefit of the IDEA Drive GUI is the automatic population of the motor and drive parameters based on entering the actuator part number when prompted by the user interface. Complex parameter calculations or in-depth stepper motor knowledge from the user is completely unnecessary. For a more experienced user, auto-populated values can easily be adjusted as long as they remain within the safe range calculated by the software.

Haydon Kerk's family of IDEA Drive Programmable Linear Actuators includes:

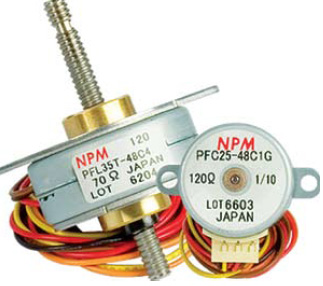

Linear Stepper Series from Nippon Pulse

Nippon Pulse's linear stepper series provides a simple motion system at a fraction of the cost of conventional rotary stepper motors and traditional linear motion systems. Our LINEARSTEP® series are permanent magnet type stepper motors that enable linear motions without the need for external transformers. The LINEARSTEP® series offers a wide range of customizable options, including various screw pitches, screw lengths, bipolar or unipolar windings, and several operating voltages.

Because of its ball bearing support and strong motor case, the LINEARSTEP® series provides you with durability and a long operating life. With an enhanced Neodymium rotor magnet, the LINEARSTEP® series also offers a large driving force, up to 39.5N at 200pps. These linear motors can be controlled and driven by the same electronics used for rotary stepper motors.

Features

LINEARSTEP® motors offer direct linear motion without any mechanical transformers and therefore allow you to design a simple system at a fraction of the cost of conventional rotary stepper motors. The PFL, PFCL series offers the design engineer the ultimate in flexibility to match the applications requirements. Features include:

- Offered in diameters of 25mm and 35mm

- Can also be ordered with one of three thread pitches on the lead screw (0.48mm, 0.96mm, and 1.2mm)

- Unipolar or bipolar windings with a variety of useable voltages

- 30mm and 60mm effective stroke lengths

- 12V and 5V coil ratings

- 24 or 48 steps per revolution

- Forces between 8N and 39.5N (at 200pps)

- Travel per step between 0.01mm and 0.05mm

- Step angles of 7.5° and 15°

- Rated current between 0.10A/F and 0.42A/F