Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

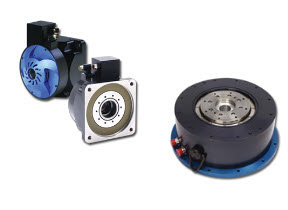

| C041A (240 VAC)108mm Frame Size, 4.57 Nm Max Cont. Torque, 1750 RPM Max Speed Request Quote | View Details |

| QTR-A-78 Series - 17-NOptimized for low voltage applications with a small build-space available. Peak 0.8-7.5Nm. Continuous 0.55-4.75Nm $475.00 As low as $433.00 | View Details |

| QTR-A-78 Series - 25-YOptimized for low voltage applications with a small build-space available. Peak 0.8-7.5Nm. Continuous 0.55-4.75Nm $560.00 As low as $519.00 | View Details |

| QTR-A-160 Series - 34-NPeak 6.2 - 58.3 Nm. Continuous 4.1 - 36.3 Nm. $1,350.00 As low as $1,324.00 | View Details |

| C041B (240 VAC)108mm Frame Size, 4.52 Nm Max Cont. Torque, 2500 RPM Max Speed Request Quote | View Details |

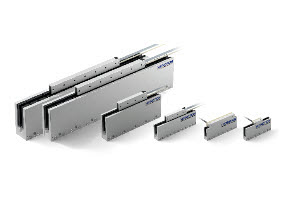

| UF Ironless SeriesIronless, 39 N Max Cont. Thrust Force (85 N Peak), 5.1 m/s Max Speed Request Quote | View Details |

| UM Ironless SeriesIronless, 116 N Max Cont. Thrust Force (400 N Peak), 18 m/s Max Speed Request Quote | View Details |

| TL Ironcore SeriesIron Core, 840 N Max Cont. Thrust Force (1600 N Peak), 7 m/s Max Speed Request Quote | View Details |

| TM Ironcore SeriesIron Core, 360 N Max Cont. Thrust Force (630 N Peak), 12 m/s Max Speed Request Quote | View Details |

| TB Ironcore SeriesIron Core, 1900 N Max Cont. Thrust Force (4000 N Peak), 6 m/s Max Speed Request Quote | View Details |

| TBW Ironcore SeriesIron Core, 3000 N Max Cont. Thrust Force (6000 N Peak), 6 m/s Max Speed Request Quote | View Details |

| UL Ironless SeriesIronless, 350 N Max Cont. Thrust Force (1200 N Peak), 12 m/s Max Speed Request Quote | View Details |

| UC Ironless SeriesIronless, 20 N Max Cont. Thrust Force (72 N Peak), 5 m/s Max Speed Request Quote | View Details |

| UXX Ironless SeriesIronless, 846 N Max Cont. Thrust Force (4200 N Peak), 6.6 m/s Max Speed Request Quote | View Details |

| C042A (240 VAC)108mm Frame Size, 8.25 Nm Max Cont. Torque, 1700 RPM Max Speed Request Quote | View Details |