Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

Sierramotion

Sierramotion's mission is to pioneer the frontier of technological innovation, facilitating the creation of advanced engineering solutions that tackle complex motion dilemmas. By working closely with their clients, they develop, manufacture, and introduce products that not only solve existing issues but elevate the entire system to a new standard of excellence. From straightforward coils to complex motion assemblies functioning in vacuum environments, their seasoned expertise guarantees results that perfectly align with your expectations right from the beginning.

What Sets Sierramotion Apart:

- Tailored Solutions: Their dedicated team collaborates with clients to craft products that address intricate motion complications, eliminating the necessity for numerous iterations.

- Streamlined Transition to Mass Production: Sierramotion paves the way for a smooth shift from prototype to large-scale production, connecting you with globally competitive manufacturing resources when needed.

- Multi-Faceted Expertise: Utilizing a network of specialists in various domains, they assemble the perfect development team to tackle your specific challenge, all managed by experienced project leaders.

Sierramotion's Core Product Lines Are Ideal For:

- Robotics

- Motor Systems and Drives

- Mechatronic Assemblies

- Control Systems

- Human-Machine Interfaces

- Dynamic Vibration and Fluid Dynamics Analysis

- Magnetic Bearings and Mechanical Design

- High-Speed Rotary Dynamics

Sierramotion Specializes in Merging These Areas to Develop Advanced Solutions:

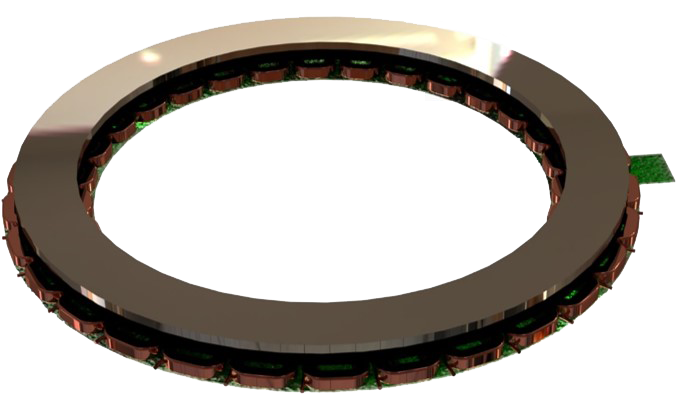

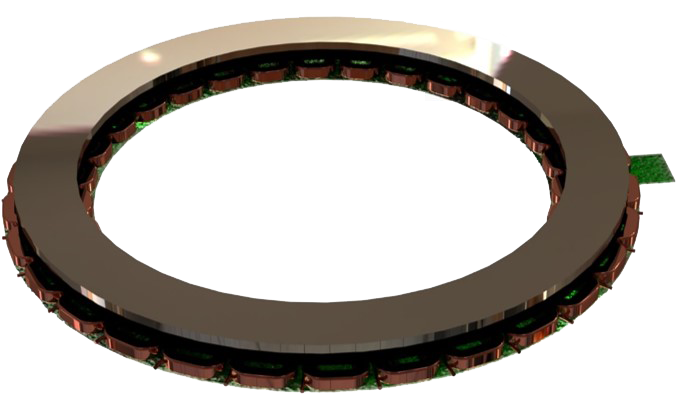

- Arc-Shaped limited angle actuator assembly

- Large-diameter axial flux modular motors for gantry imaging systems

- Direct drive axial flux motor kits suitable for camera gimbals

- Linear actuators developed for implantable medical devices

- And many other diverse applications, including solutions for the rapidly growing micro-EV market in Southeast Asia.

Sierramotion is Transforming the Landscape of Motion Components:

Motion components can range significantly in complexity, from basic elements like coils and magnets to advanced systems encompassing special Titanium enclosures. These components are instrumental in constructing larger, more efficient systems, allowing manufacturers to prioritize performance while minimizing unnecessary parts or couplings. This methodology, once exclusive to high-volume projects, has now become mainstream, finding its place in a plethora of machines and products.

In the robotics sector, currently the fastest-growing market, Sierramotion has a significant role to play. Contemporary robots feature a series of finely integrated components within each joint, moving away from the conventional practice of using shafts and couplings for motor attachment. Sierramotion excels in crafting motors and mechatronic systems that perfectly cater to your application requirements. With finite element analysis tools for magnetic, mechanical, and thermal simulations, they can conceive optimal solutions in a mere matter of hours.

For more intricate scenarios, the team can undertake computational fluid dynamics simulations to create active cooling flow analyses and even engineer fluid dynamic bearings. This comprehensive approach ensures a harmonized solution that meets all critical design parameters.