Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

Downhole & MWD Motors

Measurement While Drilling in Oil & Gas exploration applications

Today over 85 percent of the world’s energy use is based on fossil fuel sources such as coal, oil and gas. However reaching the resources requires the need to drill deeper than ever before which is not a simple exercise. Down hole deep drilling equipment opens the possibility of recovering resources from depths greater than 2.5km. Recent developments allowing down hole drilling equipment to be directionally controlled has given access to formerly inaccessible oil reserves. Now drilling to 5km down and 11km across is even possible.

Extremely tough environmental conditions are commonplace globally for drilling equipment, the demands on the drill head in particular are at the highest. Heavy duty brushed & brushless DC motors need to withstand the intense vibration, pressure and heat. The heavy duty brushless DC motor range produced by maxon are not only designed for but are rated and tested to meet these conditions. Combined with new electronics technology they allow for improved control and monitoring of drilling procedures.

For Downhole/MWD Requirements – Choose your ideal maxon solution:

Mud flow power and more.

Using magnetic couplings a back driven motor becomes a generator. Using the mud flow for the drill turbine the brushless DC motor power is then harnessed for localised electronics in the drill head avoiding the need for batteries. The drill head position can also be detected and adjusted on the fly. This process is called Measurement While Drilling (MWD). This technology converts sensor data into pulses that are transmitted to the drilling platform. maxon heavy duty motors can actuate the mechanism, forming the communication pulses. maxon heavy duty DC motors also actuate hydraulic valves within the drill head.

The Measurement While Drilling (MWD) technique uses a measurement module located behind the drill head in the string of a downhole tool. The tool’s control system measures variables such as angle, vibration, and drilling speed. The “pulser” unit sends the collected information back to the surface, across several thousand meters, through pulses in the drill mud (MPT – Mud Pulse Telemetry). The pulses are generated by the actuator system that is driven by maxon’s Heavy Duty brushless servo motor assembly.

maxon heavy duty motors are also available with corresponding gearboxes. The gearboxes are manufactured with the same extreme operating environments in mind. The applications typically require elevated torque for very low duty cycles. For example: Generating the mud pulses and actuating the hydraulic valves. A unique feature of the heavy duty gearbox is the through holes in the gear housing. These are ports that allow the gearhead to be submerged in oil and they facilitate the possibility for oil to circulate through the gearbox and provide elevated heat-sinking. The heavy duty DC motor also contains the oil ports and can also be used submerged in oil or in free air. The gearmotors are manufactured entirely devoid of structural adhesives giving it the capability of withstanding extreme temperatures. This is also of particular importance when using the motor in vacuum conditions avoiding the contamination of the vacuum via outgassing. The heavy duty motor range is designed to withstand temperatures over 240°C at pressures up to 1,733 atmospheres. They can withstand vibrations to 25 Grms, impacts to 100 G.

High efficiency DC motors at great depths

The maxon heavy duty motor range features efficiencies of up to 88% in air and over 70% submerged in oil. This makes it an ideal solution for any extreme environment such as aerospace and heavy industry. They have zero cogging making them easy to control and suitable for precise positioning.

Downhole Applications:

Additional downhole applications serviced by downhole & MWD motors such as maxon's heavy duty brushless servo motors include:

- Wireline Tools

- Rotary Steerable Systems (RSS)

- Downhole Power Generation

- Pipe Cutters

- Logging While Drilling (LWD)

- Valve Control

The benefits of maxon’s Heavy Duty brushless Servo Motors & Gearmotors include:

- Operating temperatures (-55°C… 240°C)

- Withstands high shock loads and vibrations: 1000G / 25 Grms

- Operates at high pressure (up to 1,733 bar)

- Highly reliable, even in harsh environments

- Motors can run in air or fully submerged in oil

- Motors can operate with optional high-temperature hall effect sensors or in sensorless operation with electrical motor controllers

Directional Drilling

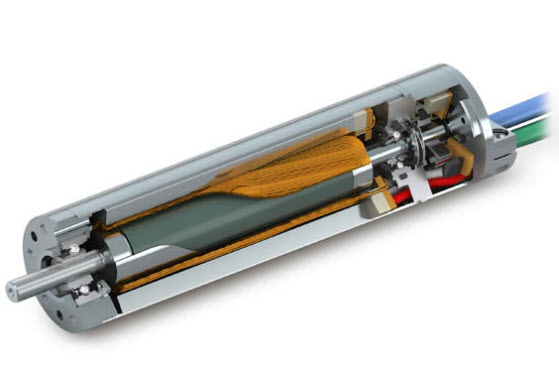

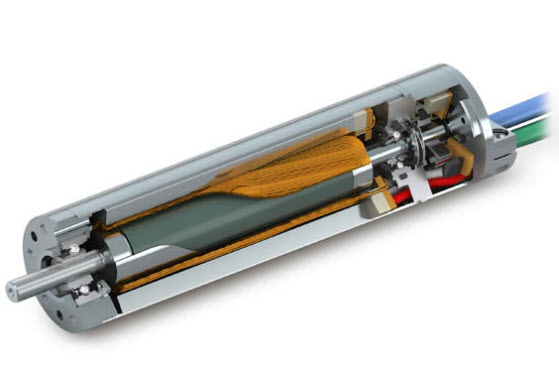

Withstands temperatures of more than 200 degrees: the maxon EC22 HD motor. © 2012 maxon motor

A view of the inside of the EC22 HD motor with the special coil, System maxon. © 2012 maxon motor

maxon motor also offers a matching gearbox for the EC22 HD: the GP22 HD. © 2012 maxon motor