A direct drive linear motor provides direct linear motion (rather than rotary). Electromagnetic force is utilized to produce thrust directly, eliminating the need for rotary to linear conversion. Advantages of linear servo motors include: high speeds, high precision, fast response, stiffness, zero backlash and maintenance free operation. Disadvantages include: higher cost, required higher bandwidth, larger footprint and heat. Types: Iron core, air core, and slotless.

Nippon Pulse Linear Motors

The Linear Shaft Motor, from Nippon Pulse, is a simple, high efficiency, high precision brushless direct drive servo motor that requires no maintenance over its lifetime. The tubular motor consists of only two parts: a magnetic shaft, and a “forcer” of wound coils. Because it has no iron in the forcer or shaft, giving you the precision and zero cogging expected in a coreless design, the Linear Shaft Motors provide ultra-high precision.

The coils of the Linear Shaft Motor form the core, giving you the stiffness expected in an iron cored motor. Because the coil completely wraps around the magnets, all the magnetic flux is efficiently used. This allows for a large (0.5 to 2.5mm) nominal annular air gap. This air gap is non-critical, meaning there is no variation in force as the gap varies over the stroke of the device.

The Linear Shaft Motor can replace ball-screws, pneumatics, u-shaped motors, and other linear motion systems. It is ideal for biomedical, packaging, printing, automation, and many other applications.

Click on the following link to download a Linear Shaft Motor Application Worksheet which you can email to us at sales@electromate.com to generate your quote.

Design Concepts of the Linear Shaft Motor:

- Simple: Two parts and a non-critical air gap

- Non-Contact: No wearing and maintenance free

- High Precision: Ironless design and all the magnetic flux is used

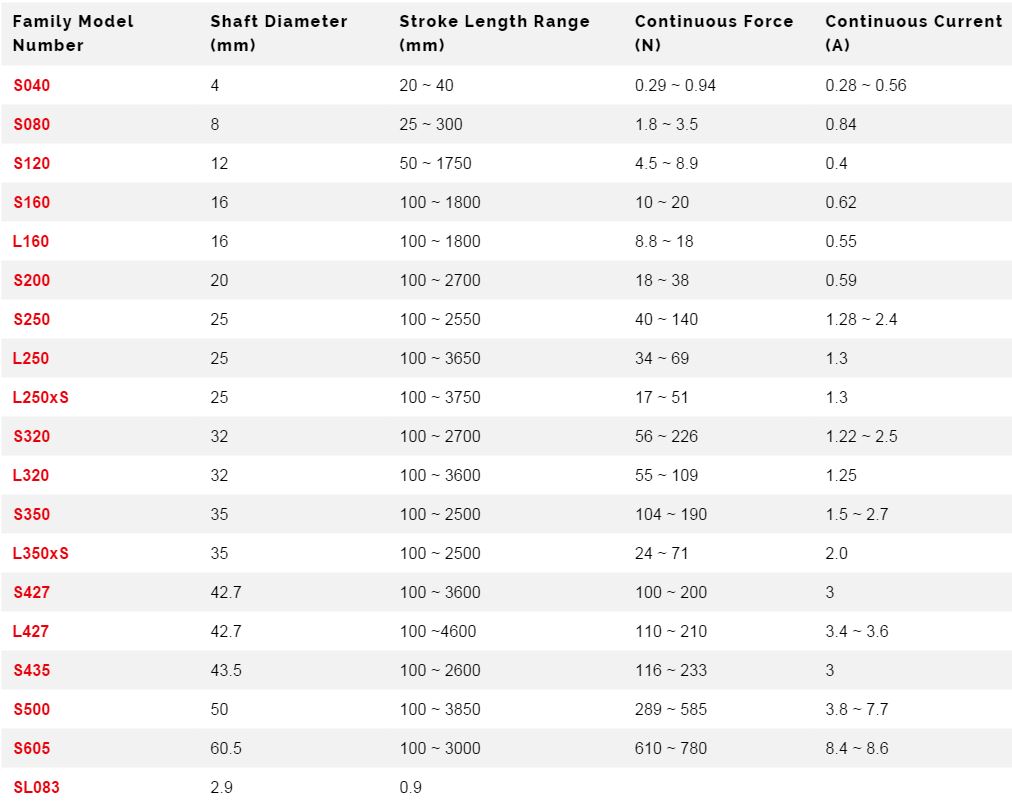

Linear Shaft Motor Specification Overview:

- Variety of shaft diameters, ranging from 4mm to 100mm

- Stroke lengths of 20mm to 4.6M

- Achievable peak force of 2340N

- Maximum continuous force of 780N

Selection Chart:View More

Tecnotion Linear Motors

Tecnotion is the global authority on linear motor technology. We are the world's only unbundled manufacturer of linear motors. A former part of Philips, we specialize solely in the development and production of linear motors. Because of this, our expertise, customer service and product quality are unmatched.

Ironcore Linear Motors from Tecnotion B.V. have a low magnetic resistance. The ironcore and the magnet closing plate are excellent flux conductors, so only the magnets and a single air gap contribute to the resistance in the circuit. Due to this low resistance, the ironcore motor's operation involves a strong flux, yielding high forces and excellent efficiency.

That makes this type a real workhorse with the following main features:

- High peak force density

- High continuous force density

- Relatively low heat dissipation

Selection Chart:View More

Ironless Linear Motors characteristics are mainly influenced by the dissimilar magnetic resistance. In this type the resistance is formed by the magnet height, two air gaps plus the coil's thickness. This results in a relative high magnetic resistance causing a low magnetic flux.

Therefore this type of linear motor is characterized by:

- A moderate peak force density

- A low continuous force density

- More heat dissipation compared to the ironcore linear motor

On the other hand, because the design is balanced and the coil section contains no magnetic material, the ironless motor has no attraction force at all, and there is absolutely no cogging. The only force generated is the thrust force. Because of the high magnetic resistance, the coil's inductivity is relatively low allowing high rates of change for very quick movements and very quick reactions to disturbance forces. These characteristics make ironless linear motors very dynamic which achieve very short settling times and high speeds.

A disadvantage of ironless linear motors is that the sandwich requires a double row of magnets making the magnet yokes rather expensive compared to the ironcore types.\

Selection Chart:View More