Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

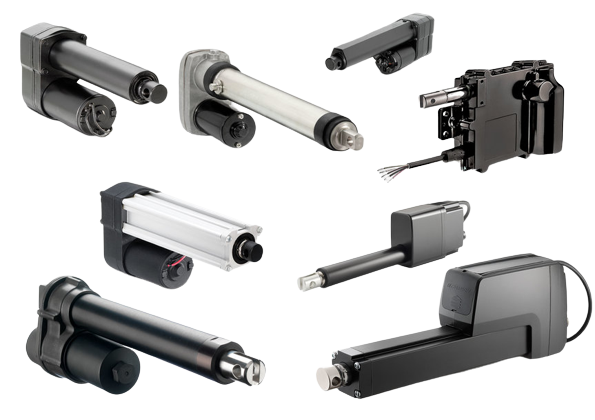

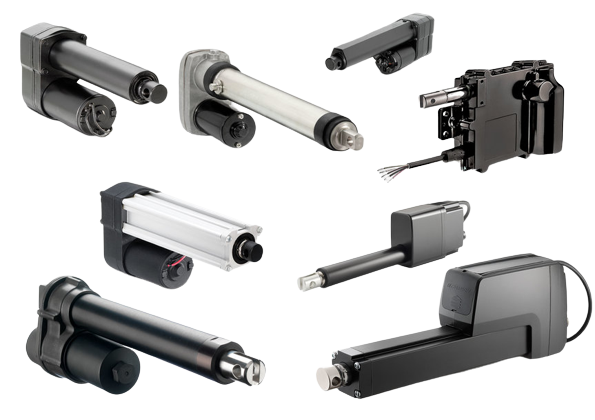

Thomson Linear Actuators

Thomson Linear Actuators provide an electric alternative to traditional hydraulic and pneumatic systems. By converting rotary motion from gears and ball or lead screws into linear motion, they achieve accurate and consistent operations.

Thomson Linear Actuators provide an electric alternative to traditional hydraulic and pneumatic systems. By converting rotary motion from gears and ball or lead screws into linear motion, they achieve accurate and consistent operations.

Thomson Linear Actuators are engineered with longevity in mind. Designed for extended use, these actuators stand out due to their minimal maintenance requirements, and users won't encounter issues related to fluid leakage.

For those seeking guidance or additional resources, Thomson provides comprehensive online support. This includes invaluable product selection tools, 3D models for visual insight, and instructional content to ensure optimal product integration and application.

When delving into performance metrics, these actuators are nothing short of impressive. With stroke lengths reaching up to 36 inches, operational speeds of 3 in/sec, and an outstanding load capacity of 3600 lbs, they remain dependable even at a 25% duty cycle when fully loaded.

The design intricacies further reinforce their efficiency. Each actuator is equipped with an autonomous electric motor responsible for translating rotary action into linear motion. Additionally, the integrated circuitry ensures a multitude of control functions, streamlining operations.

Thomson Linear Actuators are a paragon of adaptability. The newer models in the lineup are exceptionally versatile, built with features that make them suitable for a myriad of applications. In terms of construction, their compact design stands out, but this doesn't come at the expense of durability. These actuators are robust and tailored to operate seamlessly in challenging environments.

One of the primary advantages of these actuators is their clean operation. Absent the need for oils or compressors, they are the go-to option for settings where cleanliness is a priority. Delving into the realm of smart technology, many of Thomson's actuators are advanced, outfitted with onboard controls that pave the way for enhanced operational monitoring. Lastly, the long-term economic benefits are undeniable. Electric actuators, like the ones from Thomson, translate to considerable savings over extended periods. This can be attributed to factors like reduced power consumption during inactivity, the preference for cables over tubes in design, and their inherently low maintenance nature.

Thomson Linear Actuators provide an electric alternative to traditional hydraulic and pneumatic systems. By converting rotary motion from gears and ball or lead screws into linear motion, they achieve accurate and consistent operations.

Thomson Linear Actuators are engineered with longevity in mind. Designed for extended use, these actuators stand out due to their minimal maintenance requirements, and users won't encounter issues related to fluid leakage.

For those seeking guidance or additional resources, Thomson provides comprehensive online support. This includes invaluable product selection tools, 3D models for visual insight, and instructional content to ensure optimal product integration and application.

When delving into performance metrics, these actuators are nothing short of impressive. With stroke lengths reaching up to 36 inches, operational speeds of 3 in/sec, and an outstanding load capacity of 3600 lbs, they remain dependable even at a 25% duty cycle when fully loaded.

The design intricacies further reinforce their efficiency. Each actuator is equipped with an autonomous electric motor responsible for translating rotary action into linear motion. Additionally, the integrated circuitry ensures a multitude of control functions, streamlining operations.

Thomson Linear Actuators are a paragon of adaptability. The newer models in the lineup are exceptionally versatile, built with features that make them suitable for a myriad of applications. In terms of construction, their compact design stands out, but this doesn't come at the expense of durability. These actuators are robust and tailored to operate seamlessly in challenging environments.

One of the primary advantages of these actuators is their clean operation. Absent the need for oils or compressors, they are the go-to option for settings where cleanliness is a priority. Delving into the realm of smart technology, many of Thomson's actuators are advanced, outfitted with onboard controls that pave the way for enhanced operational monitoring. Lastly, the long-term economic benefits are undeniable. Electric actuators, like the ones from Thomson, translate to considerable savings over extended periods. This can be attributed to factors like reduced power consumption during inactivity, the preference for cables over tubes in design, and their inherently low maintenance nature.