The choice between a servo and stepper motor is an important decision in any system design. In general, the higher the performance requirement (high precision, variable load, high duty cycle, high torque vs. speed) the more likely a servo will be the choice. Where budget is more critical, performance is not crucial, and simple set up is needed, a stepper solution is a cost-effective option.

The below compares the performance of brush/brushless servo and stepper motors:

|

Parameter: |

Servo: |

Stepper: |

|

Cost |

Moderate |

Low |

|

Load |

Can Vary |

Constant Loads |

|

Inertia Loads |

Good |

Poor |

|

Speed |

High |

Low-Moderate |

|

Motion Profiles |

Complex |

Simple |

|

Axes of Control |

Single/Multi |

Primarily Single |

|

Precision |

Excellent |

Good |

|

Motor Dynamics |

Excellent |

Average-Good |

|

Power |

Fractional to 15 HP |

< 1 HP |

|

Efficiency |

Energy Efficient |

Energy Inefficient |

|

Maintenance Required |

Low (Brushless)/Moderate (Brush) |

Low |

|

Tuning Difficulty |

Moderate-High |

Low |

|

Torque-Weight Ratio |

High |

Moderate |

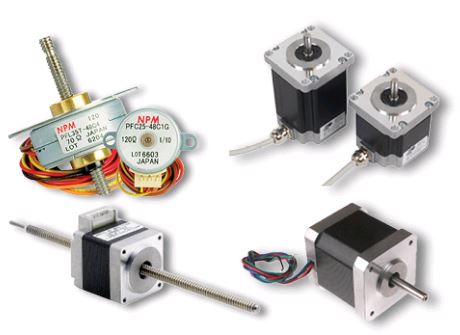

With stepper motors, closing the position loop with an encoder is not an effective means of providing increased precision. Whereas the encoder will provide position verification, the step motor is unable to “servo” to ensure high dynamic performance and repeatability. Adding an encoder and using a microstep driver makes the relative costs of servo and stepper systems roughly equivalent, yet the performance remains decidedly better with servos.