Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

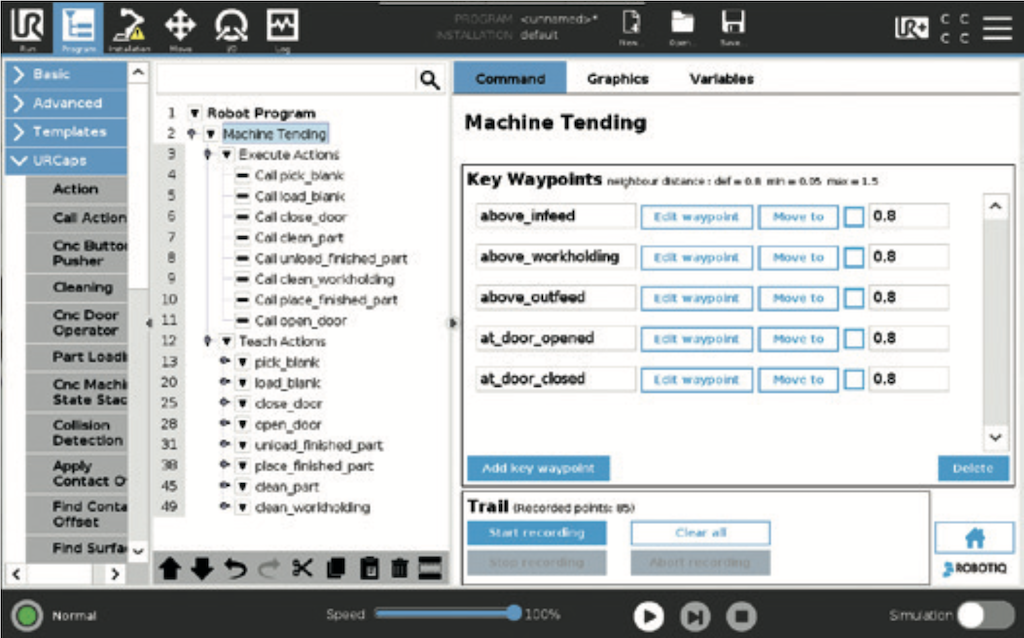

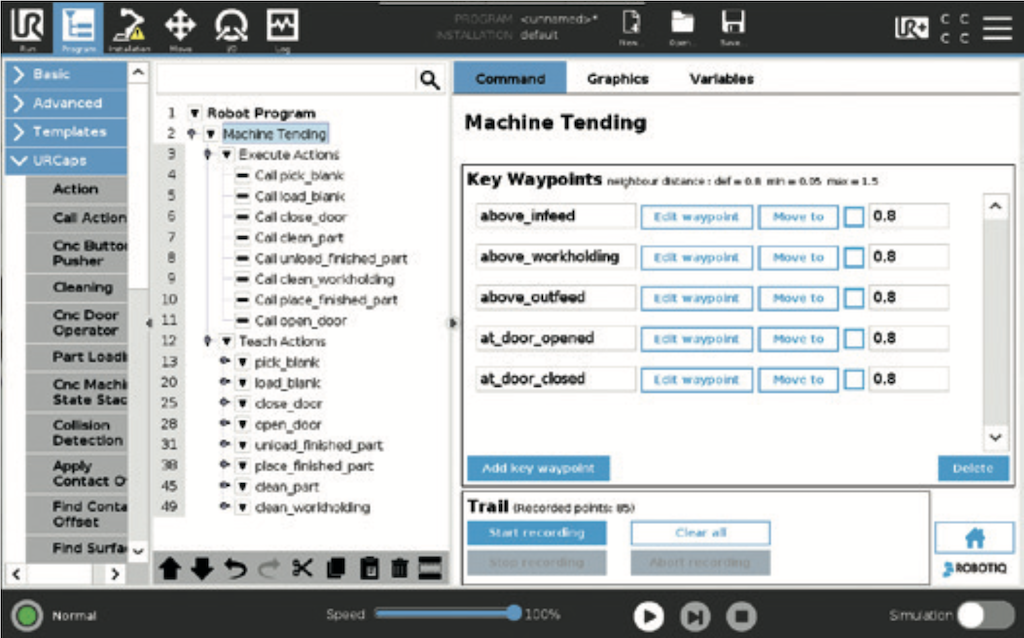

Universal Robots CNC Machine Tending Kit

Getting robots up and running doesn't need to be difficult. Increase your production hours and reduce downtime with an easy-to-use CNC Machine Tending Solution that does the work for you.

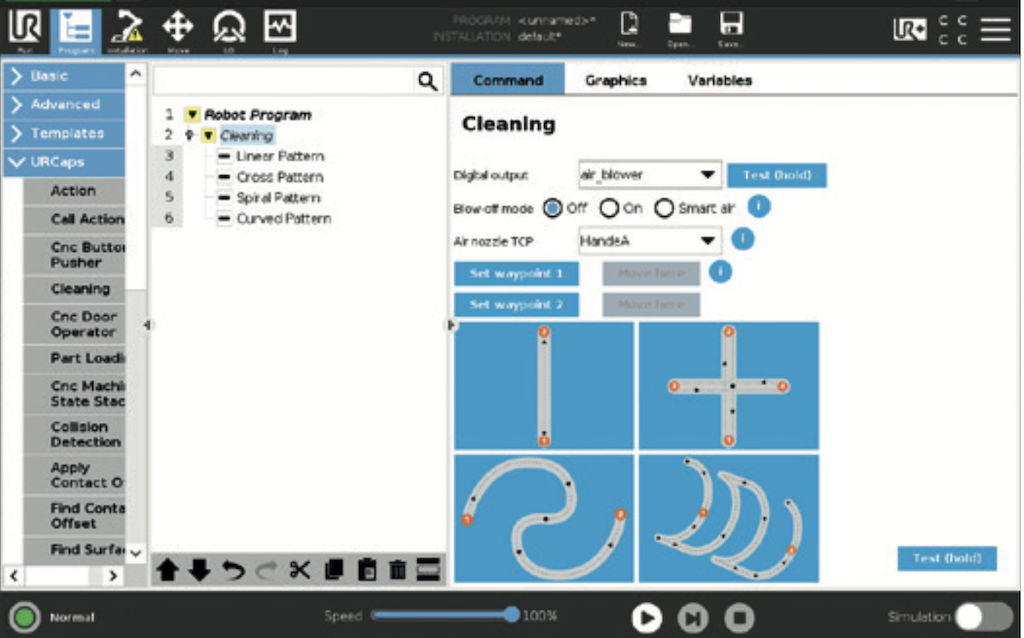

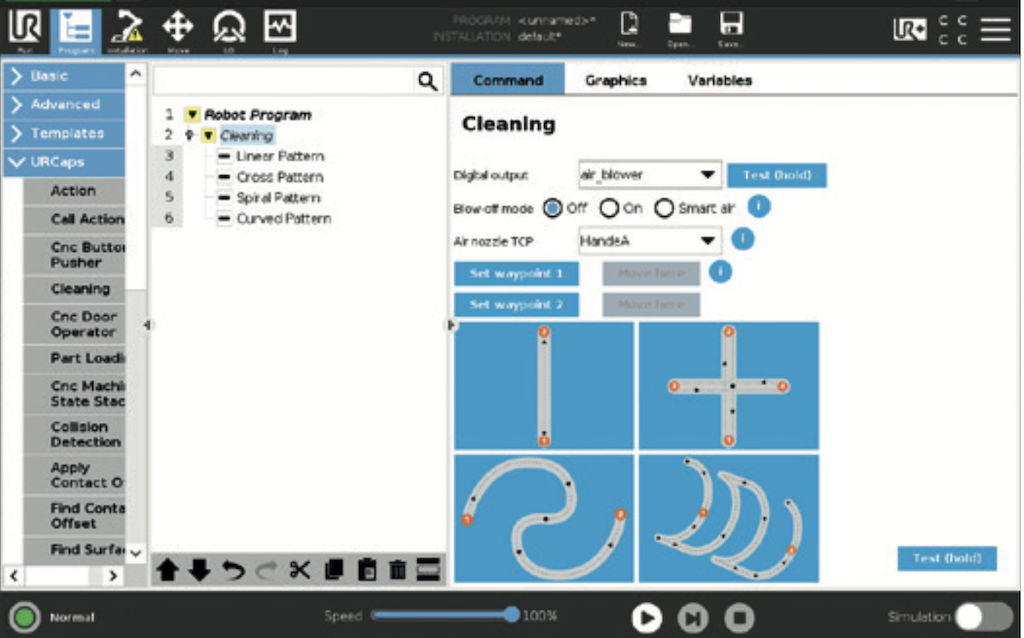

The CNC Machine Tending Solution combines technologies from Robotiq and Universal Robots, and will guide you through programming from start to finish. It makes a complex application simple. There is no need to open or alter your machine in any way. External modules manage communication with the machine interface, meaning it will work with any brand of CNC machine. This approach will greatly reduce your deployment time.

The Machine Tending Solution delivers peace of mind that your machines will always keep running through accessible automation. High-mix, low-volume automation is finally viable with the accelerated deployment and changeover made possible by the Machine Tending Copilot. Now any batch size can be automated.

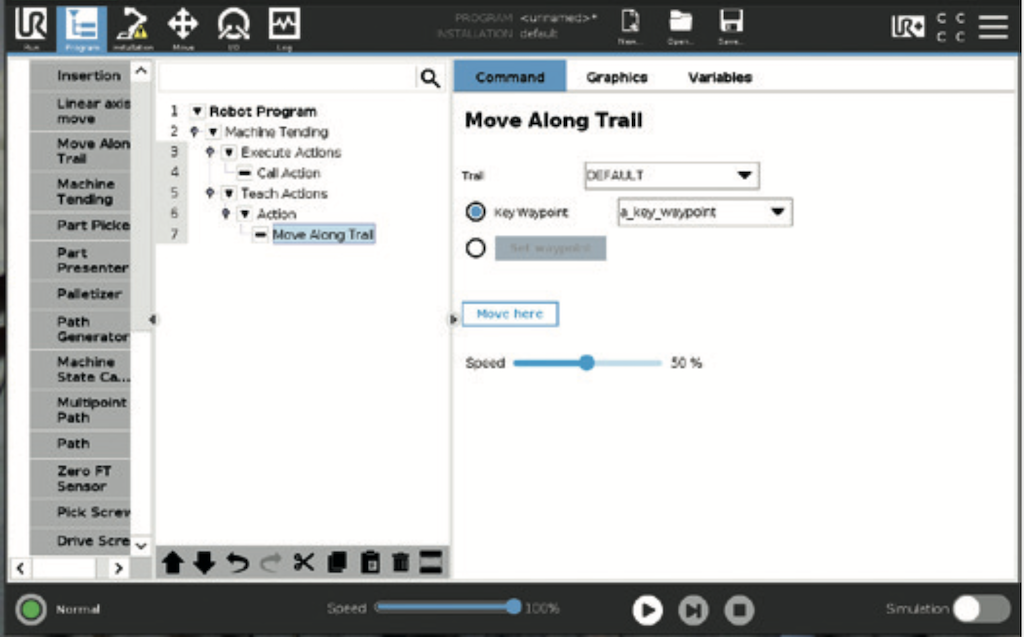

Create programs 75% faster than with traditional programming, thanks to guidance on setting key waypoints and simple action menus. All it takes is three simple steps:

1. Sey Key Waypoints

Once they're set, they become the reference points for your operations.

2. Refine Operations

Use our action menus and adapt the solution to your needs.

3. Create your Smart Moves

Machine Tending Copilot creates optimized movements between your key waypoints, finding the best path through the pre-defined flyzone and automatically avoiding collisions within the workcell.

Sample image only. Product may differ